This past weekend I met with a good friend willing to help me edit my thesis. He is an Exercise and Movement Scientist and Sport Psychologist who is not only an incredible writer, but engages me in stimulating conversation on the topic of Exercise Science for hours at a time. This most recent meeting proved to be quite a surprise – for both of us! He actually accused me of speaking like a Motor Control Theorist rather than a Biomechanist. Gasp!

If the horror humor of that statement is lost on you, just know that these two branches of Exercise Science are known to take opposing stands on many topics relating to human movement. Since I have a rep to protect, this post is going to be pure biomechanics. I also promised in my last blog that I would get back on track with the original organization of my thesis and that means more biomechanics education coming your way.

If you have been reading along on the blog, you know that I primarily write about the behavior of connective tissues that respond to tensile loads. These tissues are collectively called fascia and include tendons, ligaments, aponeuroses. The collagen and elastin components in these tissues result in a specific behavior when exposed to a tensile load (stretch) called viscoelasticity \vis-kō-ē-las-ti-si-tē\.

Viscoelasticity combines qualities of both viscosity and elasticity. Viscoelasticity is actually a time dependent behavior that results in deformations conditional to the duration of the load. Go ahead, read that last sentence again. It’s packed with information. Got it? Okay good.

In practice, it translates to this: the effect of a stretch on your ligaments is not the same after 1 minute as it is after 3 minutes. In the modern world of yoga where 3-5 minute unsupported holds are the new kool-aid, you may find it useful to be armed with an understanding of tissue behavior so you will be empowered to make choices about how long to hold and under which types of conditions you should perform certain poses. Let’s start by taking a look at viscocity and elasticity as separate behaviors.

Viscous materials resist deformation (strain) when a load (stress) is applied. Honey, when compared with water, is an example of a viscous fluid, gradually stretching off the spoon under the constant force of gravity into a cup of tea at an increasing rate over time. Elastic materials are load dependent, but not time dependent, and return to resting length when the stress is removed. A rubber band is an example of an elastic material. If you stretch a rubber band and hold it without increasing the force of your stretch, it will not continue to get longer as time passes and will even return to baseline length after the load is removed. If viscous honey were also elastic, upon up-righting the spoon, the honey would recoil back to its original dollop cradled in the spoon’s basin. Therefore viscoelastic tissues exhibit both behaviors: they continue to deform over time but will gradually return to baseline length when the load is removed (as long as you don’t venture into plastic deformation territory.)

As with all aspects of life, the design is quite intelligent. Elasticity allows us to stored potential energy. This energy is released upon removal of the load and resting length is restored – like when releasing a slingshot. In rhythmic movements such as walking, the connective tissues store energy when stretched to help propel the limbs, economizing the energy production needs imposed on muscle tissue for movement. The viscous property dampens the elastic rebound, bringing forth smooth and controlled movements rather than the jerky and abrupt movements that would be the case if our connective tissues were solely elastic. An everyday example is an engineered damper that prevents a screen door from slamming by slowing the rate of elastic recoil.

Viscoelasticity, in addition to being influenced by time, is further influenced by both temperature and rate of applied load. A warmer viscous fluid will resist strain less than a colder vicious fluid; warm honey pours off the spoon more rapidly than cold honey. Generally, but not always, a slowly applied load will resist strain less than a rapidly applied load. Try pushing honey through a syringe at different rates; the slowest effort will be met with the least resistance. Collagen based soft connective tissues are less able to resist strain at warmer temperatures and slowly applied loads. Perhaps this is why we like to stretch slowly in hot rooms – we experience less resistance. But is that decrease in resistance a good idea? (If you are looking for me to definitively answer that question here, maybe you should check out my Welcome to My Biomechanics Blog post.)

Before we end, I’d like to be clear in saying that our tissues do not behave as honey, rubber bands or screen doors. I am using analogies to help teach some basic concepts in materials mechanics – information that structural engineers learn early on in their education. Our connective tissues have the added complications of cellular activity, the ability to remodel through collagen synthesis and degradation, sensory input to the nervous system, and animation provided by the neuromuscular system. Biomechanics alone does not explain how our tissues behave. Just as data collected in the laboratory on collagen fibrils only gives us insight into how collagen fibrils behave in a laboratory.¹ But I believe that without a biomechanics education, an understanding of movement and stretching will always be lacking.

Did I just redeem myself by speaking like a Biomechanist again?

Coming up next:

Viscoelasticity, exhibits a unique set of time and rate dependent phenomena: creep, stress-relaxation, strain-rate sensitivity, and hysteresis. We will explore them each in individual blogs and and get some insight into those popular 3-5 minute unsupported holds.

__________________________________________________

[1] Svensson, R. B., Hassenkam, T., Hansen, P., & Magnusson, S. P. (2010). Viscoelastic behavior of discrete human collagen fibrils. Journal of the Mechanical Behavior of Biomedical Materials, 3(1), 112–115. doi:10.1016/j.jmbbm.2009.01.005

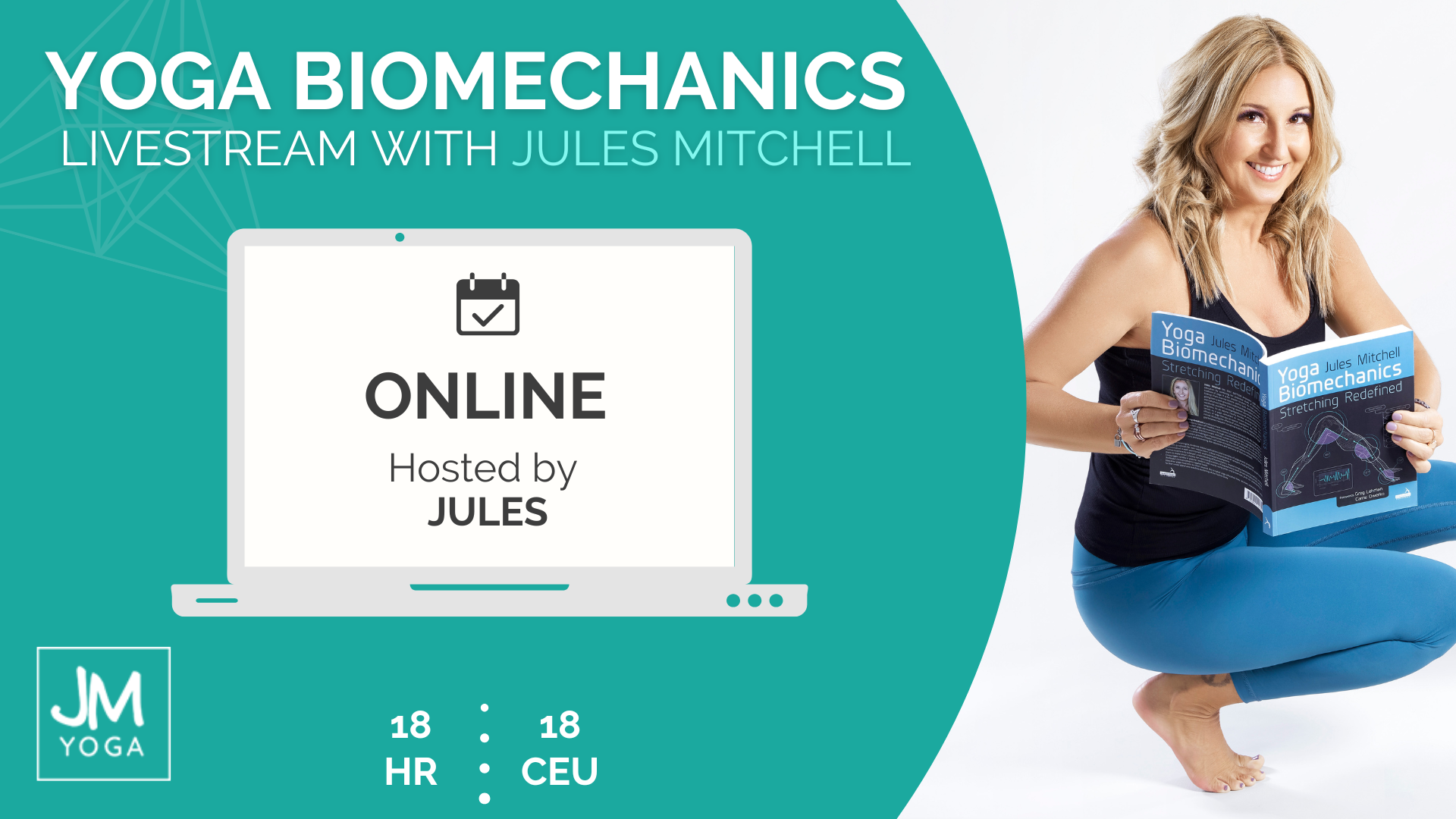

Extend Your Learning: Online Education With Jules

Yoga Biomechanics Livestream

My flagship 3-day livestream course is for teachers who have an insatiable curiosity about human movement and kinesiology, are eager to know what the research says about yoga, and are open to accepting that alignment rules aren’t always accurate. Includes 30 days of access to the livestream replay and slides. 18 CEUs. Learn more >

Thanks again for this info! I have a question… all of the info in this article and from the conversations we’ve had totally make sense to me, but I’m wondering this: does the size of the muscle, tendon, etc matter in terms of how long we hold the stretch? In my mind it does, but that’s completely based on what I feel in my body and what seems logical to me. For example, I am a big fan of Pigeon, but I wouldn’t want to just stay there for a second because it feels like I’m not relieving any tension in my glutes/hips/hamstrings/whatever hurts that day. Let’s say we’ve aligned it nicely, we’re keeping engagement in our muscles, and we stay there for a bit. How long of a bit is too long?

Hi Anna,

The size does not matter. Keep in mind the blog is about collagen based connective tissues – not muscle tissue. These tissues to not hold “tension” as they are passive and not contractile. Only muscle tissue can produce “tension”. There is an internal resistance to stretch in connective tissue, but that is not something to get rid of. If our connective tissues don’t resist stretch we would not be able to keep our shape and form. That said, if you want to hold poses for longer than 30 seconds to a minute, then I would recommend support (using props) so that you can avoid excessive elongation and allow the muscles to actually relax.

Hope that helps. We will be covering this in YTT. I hope to see you there!

Love,

Jules

Aponeuroses? Wow. Let’s here yoga teachers try to regurgitate that one. Are you referring to all asana, including strengthening standing poses or just the floor deep stretch asanas?

Hi Lisa, I’m not sure exactly what part you asking me about…but tissues are viscoelastic regardless of the type of pose. But since viscoelasticity is a time dependent quality, time will definitely influence the outcome. Creep is the first phenomenon that we looked at. If you read that one again, it doesn’t really mean much until 15-20 seconds. More to phenomena to come. 🙂